Leveling or deburring with the robot can improve ergonomics in the workplace

The metal parts are mostly processed in machines, but they still need to be loaded and unloaded; and transport between the machines also needs to be organized. Fortunately, there is a whole range of aids available: Lifting magnets, chain hoists, cranes, or robots help to lift the heavy metal parts. Unlike humans, they do not get fatigued. The skilled workers also benefit because the right technical equipment improves ergonomics at the workplace. This keeps employees healthy and leads to a decrease in absenteeism due to sick days, as well as an increase in motivation.

If you take a closer look at the processes, you will notice the loading and unloading of the leveling and deburring machines. These are comparatively monotonous activities with many repetitions. This is precisely what robots are very well suited for: They can perform the same task repeatedly without losing precision. Additionally, they can also work multiple shifts without the need for a break.

Robots with additional capabilities increase efficiencies for leveling and deburring even further

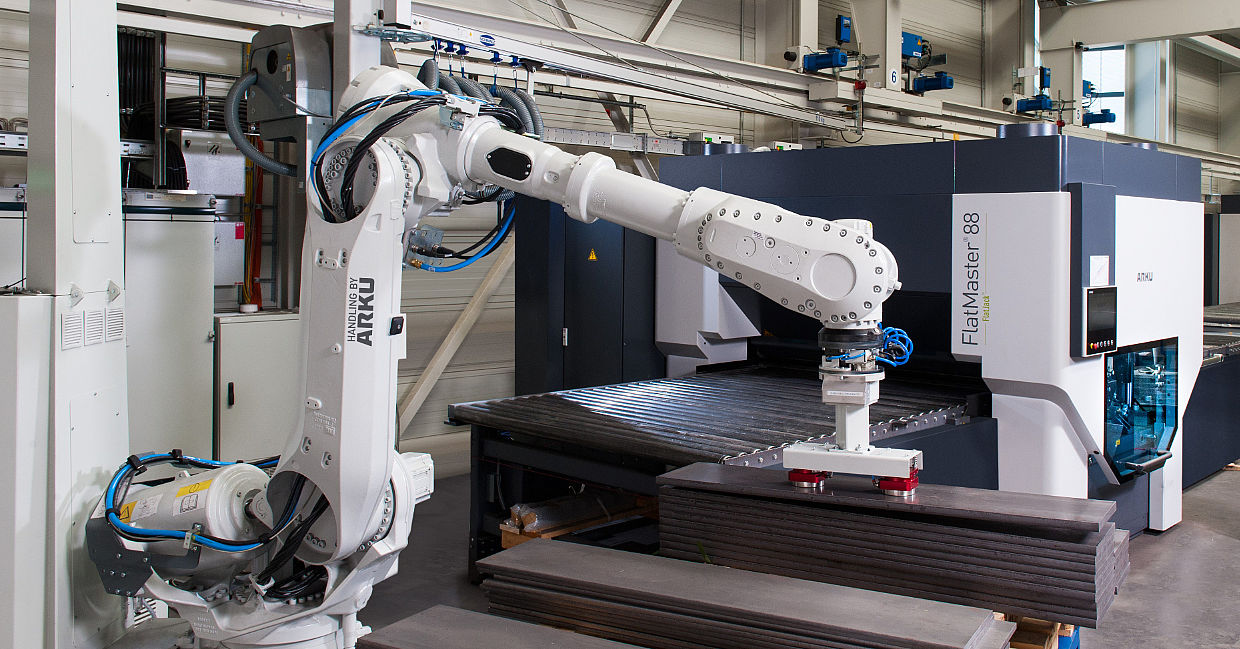

If the robots on the leveling or deburring machines are equipped with additional technology, productivity is increased further. For example, there are now self-learning robots that no longer need to be laboriously programmed. This is a decisive advantage, especially for small batches, as is often the case in sheet metal processing. Thanks to modern camera technology, a self-learning robot can move parts of different thicknesses and materials. It lifts sheets weighing up to 100 kilograms onto the infeed roller conveyor of the leveling or deburring machine. The robot is also suitable for removing the parts.

In this case, the employees have far less to do with loading and unloading the machines: They only have to position a pallet with blanks next to the system. With the help of the cameras, the robot can detect the stack height, position and orientation of the sheet metal parts. Depending on the weight and size, it selects the appropriate part gripper and lifts the blanks onto the machine's infeed roller conveyor. After leveling or deburring, the robot arm places the parts back on a pallet. The advantage of the robot is that employees are relieved of routine work and can concentrate on other tasks. In addition, the processes always run in the same way - an important prerequisite for maintaining quality standards.

Automated leveling and deburring with a robot can alleviate shortage of skilled workers

This example shows that automated leveling or deburring with robots cannot eliminate the shortage of skilled workers, but it can at least mitigate it. Especially during this current situation, it is much easier to keep current employees than to find new ones. Employees therefore within the company don’t need to fear losing their job. On the contrary, it is often the case that automated leveling or deburring with robots eliminates bottlenecks in production. There are still plenty of jobs for well-trained people.

Robot-supported handling without programming.

ARKU parts handling is the automated loading and unloading solution for your machines. It is extremely simple thanks to automatic parts recognition.